One of the most prominent issues in the world of today is green technology and the environment. Everyone is becoming conscious about the environmental costs of their actions in the world, and as a result people are taking steps to make greener and healthier decisions. One of the most concerning modern issues in regards to the environment is the amount of tyre, plastic and waste synthetic rubber that is produced and consumed in today’s modern world. Plastic and synthetic rubber always requires oil to produce, there’s really no way around it, but they’re absolutely required for our modern world to operate. There’s no way we can go back to the days before plastic, it just adds so much convenience and usefulness in our modern world. So is it possible to produce plastic and synthetic rubber without relying on environmentally unfriendly and potentially disastrous oil extraction. There is one way that looks promising by cheap waste tyres to oil machinery in Kingtiger.

Tire Pyrolysis Technology: The Way of the Future

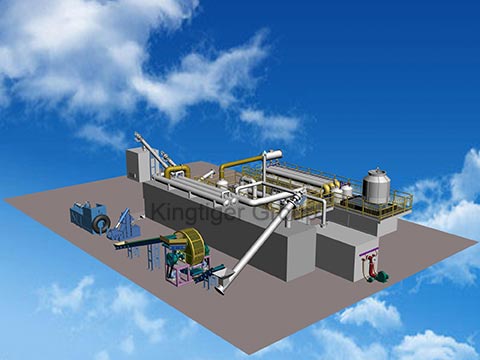

One of the most interesting modern technologies that have recently been developed is the ability to regenerate oil from scrap tyres, plastics, synthetic rubber, and other oil products by a process that’s known as tire pyrolysis technology. In the Earth, hundreds of millions of years ago, material from dead plants and animals decomposed and broke down over millions of years to form coal and oil. This process takes place slowly, and is only possible because of the high heat and pressure that acts on the biological materials deep underground. But what scientists and researchers have discovered is that it’s possible for this process to be accelerated in the industrial tires pyrolysis procedure from https://kingtigergroup.com/tyre-to-fuel-recycling-plant/.

Tyre Pyrolysis: How It Works

The way that the tyre pyrolysis process works is that plastic, tyre and synthetic rubber feedstock material is placed in a specially plastic pyrolysis unit. The feedstock material is then placed under very high heat and pressure for a rather long time, usually several weeks, and depending on the feedstock material, possible several months. This procedure mimics the natural underground processes that form oil, but there are a couple factors that make it take a couple weeks instead of a couple million years.

Tyres Pyrolysis: Why It Works

The reason that tyre oil pyrolysis proceeds so much faster than natural oil forming processes is that the heat and pressure that can be created in the industrial process is much greater than the heat and pressure that happens naturally underground. Another reason is that since tyre, plastic and synthetic rubber are made from oil, they are chemically much closer to oil than materials like wood. This means that when tyres and synthetic rubber are used as a feedstock for this process, they can very quickly return back to an oil-like state. This process is also called as the waste rubber recycling to oil machine.

This process can be especially important and useful for making use of used or damaged tires. Tires have proven to be a very difficult thing to dispose of really the only use of them is shredding them and backing them to make rubbery material for children’s playgrounds. This process returns them to a very valuable natural state. Please click this link kingtigergroup.com to get more information on waste pyrolysis.